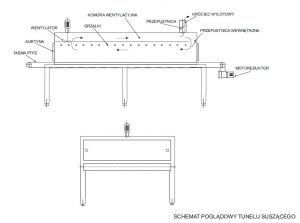

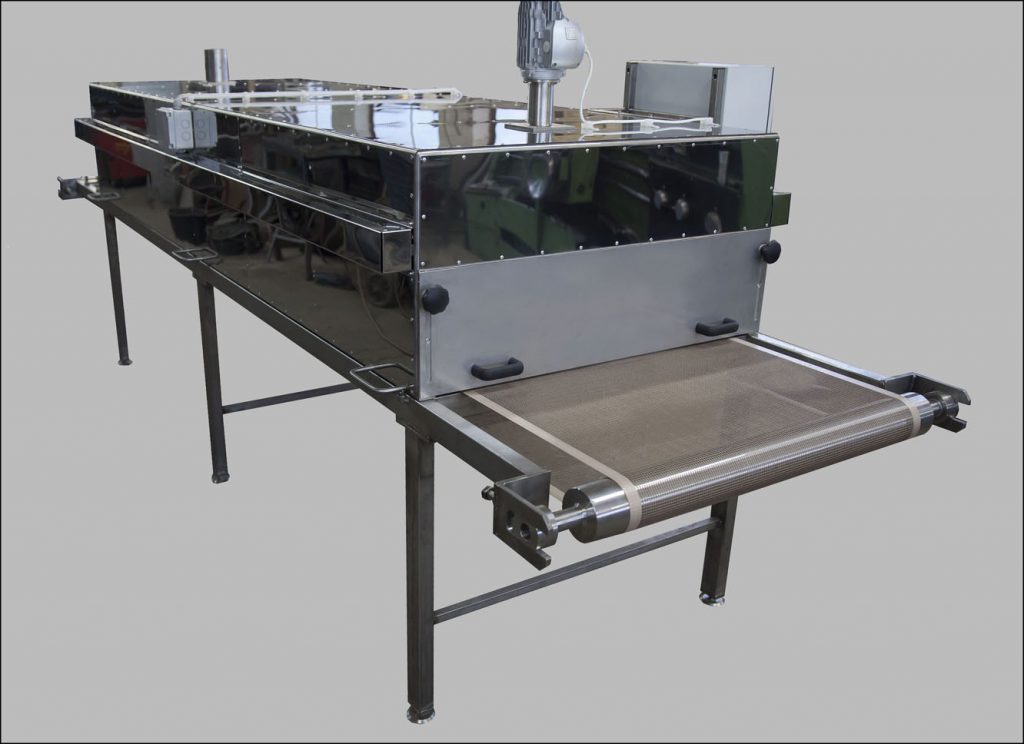

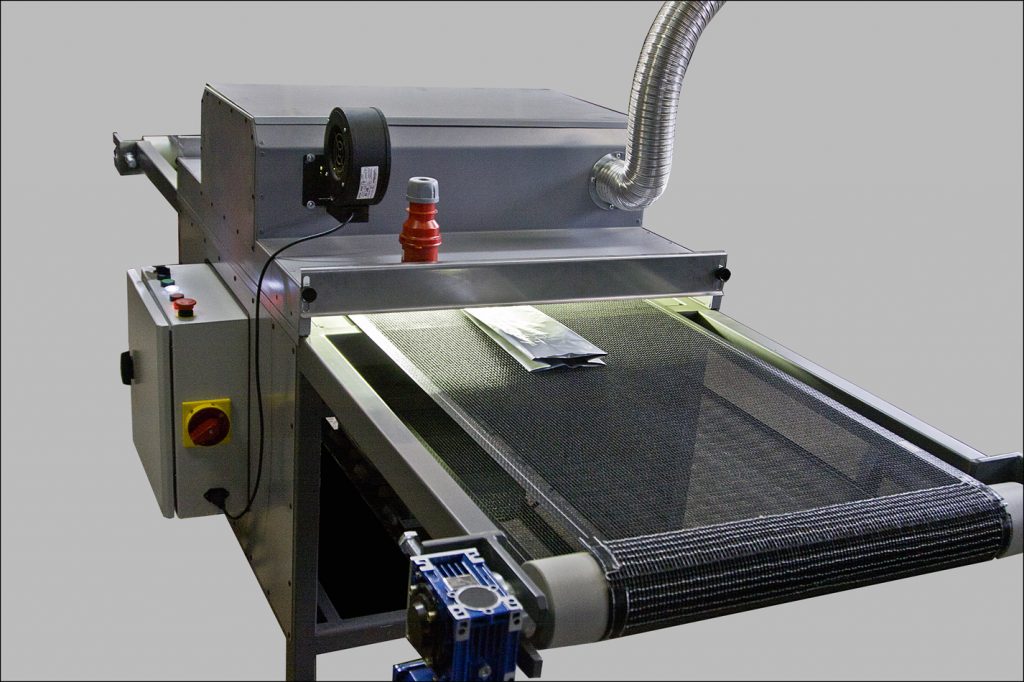

They are drying tunnels used to dry watery and plastisol prints on fabrics. Having an additional circulation zone (fig.) of the length and width of the heating zone, they are unique on the market. Thanks to that circulation zone, the air is distributed on the whole width of the heating zone. Insulated heating zone can be removed and the legs unscrewed. It enables an easy transportation. Bigger zones are created in parts with the minimum of 6 jaws to move the zone. Electric heating is installed in the exterior part. The height of the intake and exhaust nozzle can be regulated.

They are drying tunnels used to dry watery and plastisol prints on fabrics. Having an additional circulation zone (fig.) of the length and width of the heating zone, they are unique on the market. Thanks to that circulation zone, the air is distributed on the whole width of the heating zone. Insulated heating zone can be removed and the legs unscrewed. It enables an easy transportation. Bigger zones are created in parts with the minimum of 6 jaws to move the zone. Electric heating is installed in the exterior part. The height of the intake and exhaust nozzle can be regulated.

| MODEL | WIDTH

[mm] |

HEATING ZONE LENGTH [m] |

POWER

[kW] |

WEIGHT

[kg] |

| TS 800 | 800 | 3 | 15 | 480 |

| TS 1000 | 1000 | 3 | 15 | 530 |

| TS 1200 | 1200 | 3 | 18 | 580 |

| TS 1400 | 1400 | 3 | 24 | 630 |

| TS 1200/4 | 1200 | 4 | 24 | 620 |

| TS 1400/4 | 1400 | 4 | 27 | 670 |

| TS 1600/4 | 1600 | 4 | 36 | 740 |

| TS 1400/6 | 1400 | 6 | 42 | 980 |

| TS 1800/6 | 1800 | 6 | 48 | 1300 |

| TS 2200/18 | 2200 | 18 | 240 | 8200 |

Technical parameters

- Belt width, entire length, heating zone length and heating power installed – to be agreed upon

- Teflon coated fibre glass woven belt,

- 3-phase motor drive through a worm gear

- Inverter supplied motor

- Stepless adjustment and stabilization of belt run

- 1 to 5 m/min belt speed range

- 0 – 100% stepless power adjustment

- Microprocessor temperature stabilization

- Maximum temp. 180o C

- 3 independent heating zones

- Possibility of switching off each heating set (pair)

- 3 x 230 V, 50 Hz, power supply

- Circulation and ventilation air flow – stepless adjustment of circulation – ventilation ratio

- Insulated heating zone

Supplementary information:

- 24-month guarantee

- Guarantee and post guarantee service

- CE WE compliance declaration

- Work Safety and Hygiene instruction manual

- Lead time to be agreed upon

- Agreements