Carousel Screen printing presses

– the largest range of such machines and the lowest prices in Europe. They feature simplicity, robustness and well-designed construction. A wide range of adjustments and their exceptional rigidity enable very precise printing, including triad. Detailsdrying tunnels

They are drying tunnels used to dry watery and plastisol prints on fabrics.

Having an additional circulation zone (fig.) of the length and width of the heating zone, they are unique on the market.

Thanks to that circulation zone, the air is distributed on the whole width of the heating zone.

Insulated heating zone can be removed and the legs unscrewed.

It enables an easy transportation.

Flash Type IR Drying Stations

IR Power to be agreed upon (6-30KW),

6 (or more) independent drying zones,

Cooling and ventilation systems for infra-red lamps

System eliminating commutation distortion which eliminates the danger of sudden stroke of power consumption while turning on the infra-red lamps

Full power obtained within the first second after switching on,

Semi-automatic printing press for surface printing

Reliable, heavy and precise machines used to print on paper, cardboards, foil, metal plate, rubber etc.

Pneumatic frame, screen and squeegee beam drive

Mechanical squeegee carriage drive

Stepless adjustment of squeegee pressure

Squeegee rake angle adjustment

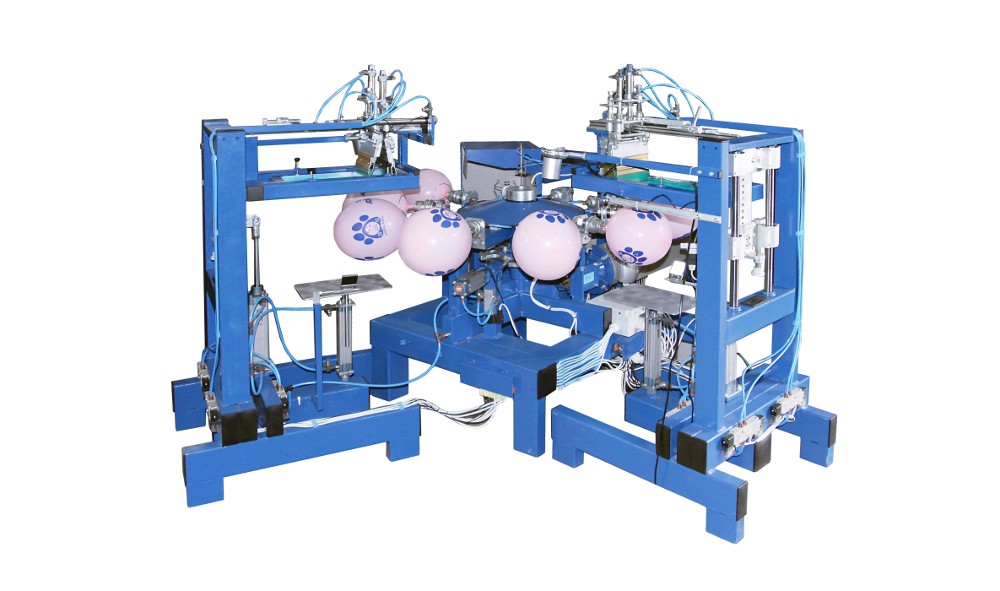

Carousel printing presses for balloons

Our offer of the machines is the most extensive in Poland. We also offer the lowest prices. The machines are characterized by rigidity and reliability of the construction.

Manual application, automatic clamping system, blowing, printing, rotation, drying and dropping

1 to 4-colour versions.

The possibility of changing the head to fasten balloons and to use different gauge collar

Regulated level of inflating, rotating speed and printed design.

Details

3/4 automats for printing on glassware

The specialized machines are designed to print on glassware. They are often configured in a way in which the glass surface is put on the exterior table, placed under the screen in the printing zone, and afterwards brought on the outside in the same or the opposite side.

Machines are often cased to eliminate air flow and dust. The prototype of such machine has been working in day and night shifts since spring 2002.

The screen is pulled out from the longer side and fixed above the floor to easily keep the hygiene

The screen is pneumatic and fixed Pneumatic table-top drive Mechanical squeegee carriage drive